Abstract:

Failure Modes and Effects Analysis (FMEA) is a critical, systematic methodology used across industries like automotive, aerospace, and manufacturing to identify potential failures in designs, processes, or systems, and to mitigate their impact. While Siemens Polarion ALM offers a robust platform for managing product development data, conducting FMEA effectively often requires specialized tools to handle its detailed, matrix-driven nature. This whitepaper, by Nextedy, illustrates how Nextedy RISKSHEET transforms FMEA within Polarion. Discover how RISKSHEET’s intuitive, Excel-like interface, coupled with powerful customization and real-time calculation capabilities, enables organizations to perform comprehensive FMEAs (including Design FMEA, Process FMEA, and adherence to standards like AIAG & VDA FMEA), ensure full traceability, and drive continuous improvement efficiently.

Introduction: The Enduring Importance of FMEA – And the Nextedy Solution

Failure Modes and Effects Analysis (FMEA) is a proactive engineering quality method that helps teams anticipate potential failures and prevent them from occurring. Whether applied to product designs (DFMEA), manufacturing processes (PFMEA), or systems (System FMEA), its goal is to improve reliability, safety, and overall product quality by:

- Identifying potential Failure Modes.

- Analyzing their potential Effects.

- Determining their potential Causes.

- Assessing the Severity (S), Occurrence (O), and Detection (D) of failures.

- Prioritizing risks, often using a Risk Priority Number (RPN) or Action Priority (AP).

- Defining and tracking Recommended Actions or Control Measures.

While Siemens Polarion ALM is a powerful ALM platform, its native capabilities may not fully optimize the highly structured and iterative nature of FMEA. Nextedy RISKSHEET is designed to bridge this gap, providing a dedicated, flexible, and integrated solution for conducting all types of FMEA directly within Polarion, aligning with standards such as the AIAG & VDA FMEA Handbook. This whitepaper explores how.

Why Polarion ALM for FMEA? The Foundation Nextedy Enhances

Polarion ALM serves as a strong underlying platform for FMEA due to its:

- Integrated Data Management: Connecting FMEA data with requirements, design elements, test cases, and change requests.

- Traceability: Allowing links between failure modes, causes, effects, and the mitigating actions or design changes.

- Configurability: Enabling the setup of specific Work Item types and fields needed for FMEA.

- Collaboration: Supporting cross-functional team involvement in the FMEA process.

However, performing detailed FMEA analysis, with its characteristic S-O-D ratings, RPN/AP calculations, and extensive lists of failure modes, often benefits from a more specialized interface. Nextedy RISKSHEET delivers this specialized FMEA workbench within Polarion.

FMEA Concepts & the Nextedy-Enhanced Polarion Implementation

A successful FMEA implementation in Polarion, powered by Nextedy RISKSHEET, involves mapping FMEA terminology to Polarion artifacts:

| FMEA Concept | Polarion Equivalent (Enhanced by Nextedy RISKSHEET) |

| FMEA Scope / Item / Function | Work Item (e.g., SystemElement, Requirement, ProcessStep). RISKSHEET allows easy linking of these items as the scope of the FMEA. |

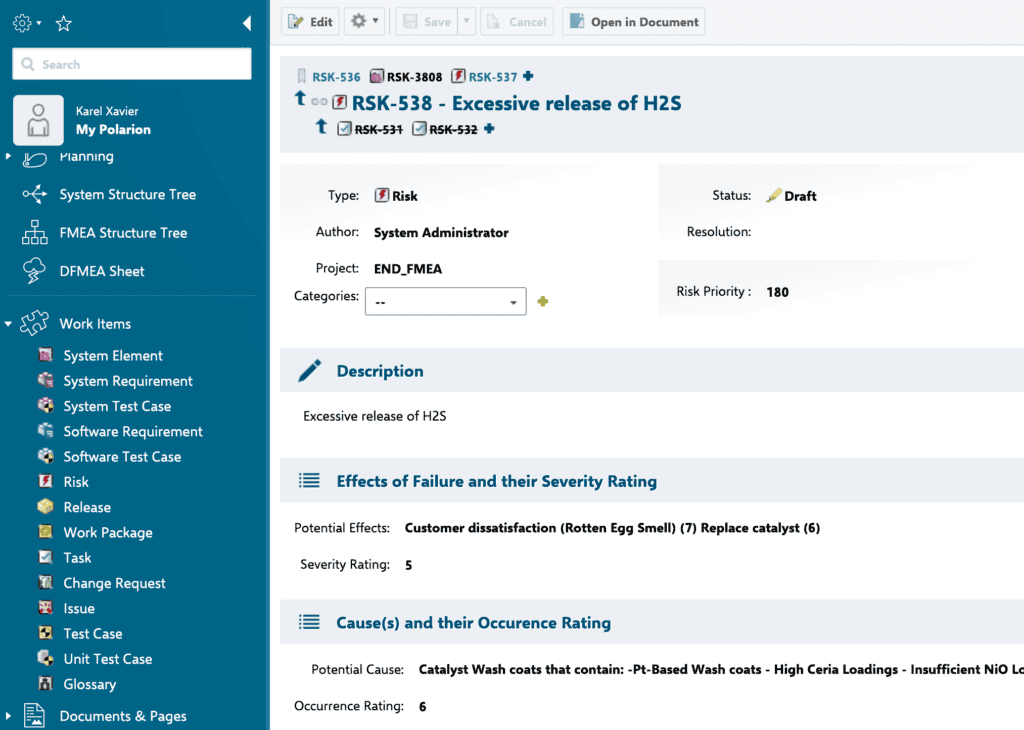

| Potential Failure Mode | Work Item (e.g., FailureMode) or a detailed description within a central FMEA record. RISKSHEET presents these in a clear, analyzable row. |

| Potential Effect(s) of Failure | Linked Work Item (e.g., Effect) or text field. RISKSHEET facilitates easy entry and linking of multiple effects. |

| Severity (S) of Effect | Custom Field (e.g., fmeaSeverity) on the Effect or FMEA record, an enumeration (1-10 scale). RISKSHEET allows direct rating selection. |

| Potential Cause(s) of Failure | Linked Work Item (e.g., Cause) or text field. RISKSHEET supports detailing multiple causes for each failure mode. |

| Occurrence (O) of Cause | Custom Field (e.g., fmeaOccurrence) on the Cause or FMEA record, an enumeration (1-10 scale). RISKSHEET enables direct rating selection. |

| Current Prevention Controls | Text field describing existing measures. RISKSHEET provides a dedicated column. |

| Current Detection Controls | Text field describing existing measures. RISKSHEET provides a dedicated column. |

| Detection (D) of Cause/Failure Mode | Custom Field (e.g., fmeaDetection) on the FMEA record, an enumeration (1-10 scale). RISKSHEET allows direct rating selection. |

| Risk Priority Number (RPN) | Calculated Field (S x O x D). Nextedy RISKSHEET calculates RPN automatically and in real-time as S, O, D are entered. |

| Action Priority (AP) | Calculated Field (based on S, O, D tables, e.g., AIAG & VDA). Nextedy RISKSHEET can implement AP logic for automatic determination and visualization. |

| Recommended Actions / Optimization | Work Item (e.g., FMEAAction, Task). RISKSHEET streamlines defining, assigning, and tracking these actions. |

| Responsibility & Target Date | Fields on the FMEAAction Work Item. Manageable and visible within RISKSHEET. |

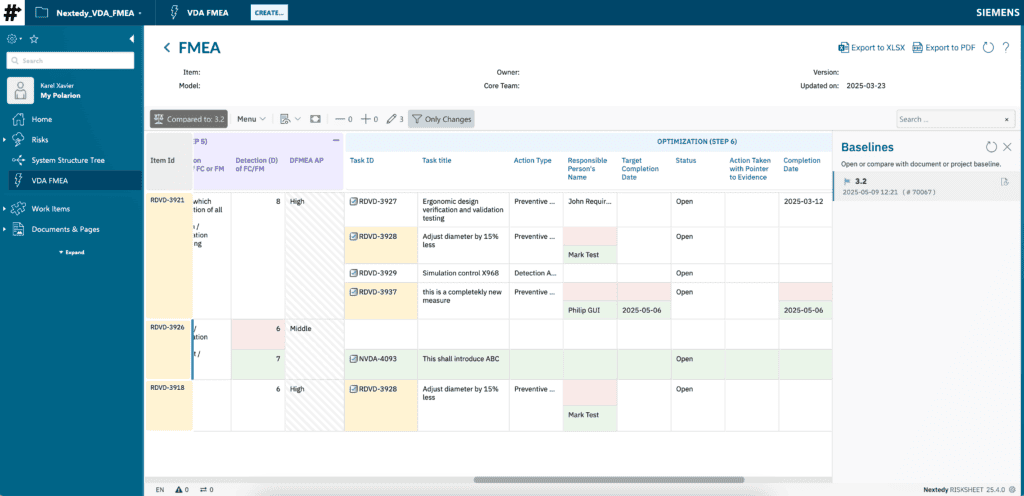

| Actions Taken & New S, O, D, RPN/AP | Fields for reassessment after actions. RISKSHEET allows for clear before/after comparison of risk levels. |

| FMEA Worksheet / Record | Polarion LiveDocument embedding Nextedy RISKSHEET, or a custom Work Item type acting as the FMEA master record. |

FMEA Structure in Polarion: Streamlined by Nextedy RISKSHEET

While Polarion allows the configuration of necessary Work Items and fields, Nextedy RISKSHEET structures these elements into a cohesive and interactive FMEA worksheet:

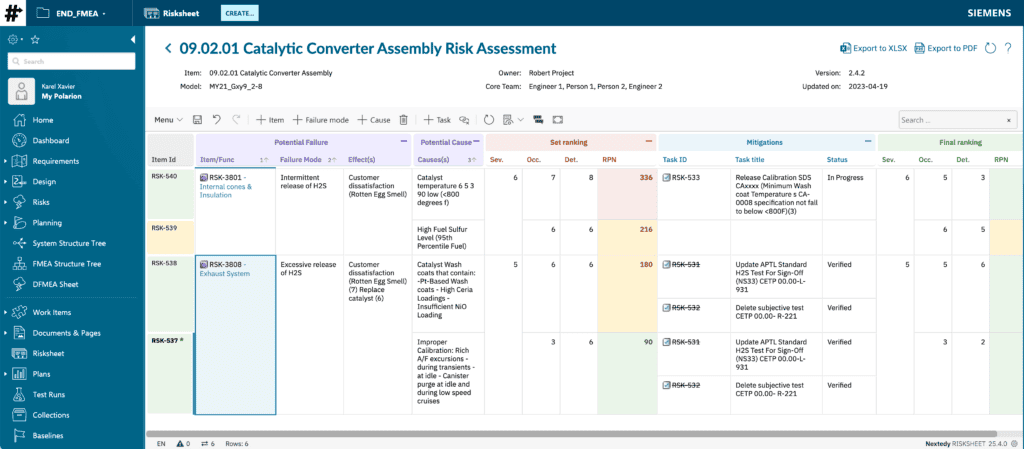

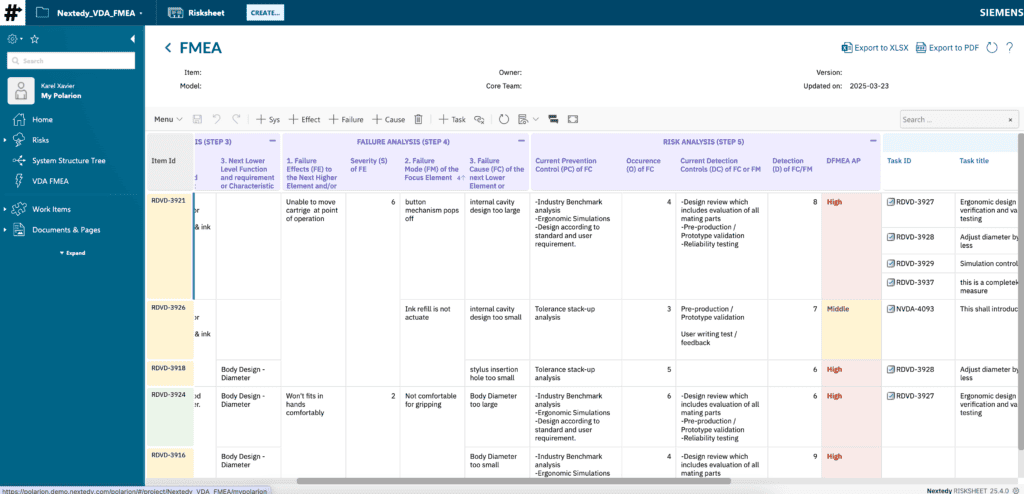

- Hierarchical Display: RISKSHEET can represent the FMEA structure (e.g., System > Sub-system > Component > Failure Mode > Cause > Effect) or a flat list, depending on the chosen methodology and configuration.

- Dedicated Columns: All standard FMEA parameters (Item/Function, Failure Mode, Effect, Severity, Cause, Occurrence, Prevention Controls, Detection Controls, Detection, RPN, AP, Recommended Actions, etc.) are presented as clear columns in the RISKSHEET view.

- Real-time Calculations: As S, O, and D ratings are entered, RISKSHEET dynamically calculates RPN and/or AP, providing immediate feedback for risk prioritization.

- Visual Prioritization: Cells for RPN or AP can be color-coded based on configurable thresholds (e.g., High, Medium, Low AP), allowing teams to instantly identify areas requiring urgent attention.

- Integrated Action Tracking: Recommended actions become linked Polarion tasks, with their status and progress visible within or alongside the FMEA in RISKSHEET.

The Nextedy RISKSHEET Advantage for FMEA: Efficiency, Consistency, Actionability

Performing FMEA in Polarion with Nextedy RISKSHEET offers significant advantages over manual methods or basic ALM capabilities:

- Unparalleled Usability: The Excel-like interface makes complex FMEA data entry and review intuitive for all team members, from design engineers to manufacturing specialists.

- Ensured Consistency: Standardized FMEA templates, rating scales (for S, O, D), and AP tables (if applicable, e.g., per AIAG & VDA) are enforced through RISKSHEET’s configuration, promoting harmonization across all FMEA studies.

- Automated Risk Prioritization: Real-time calculation of RPN and/or Action Priority eliminates manual calculation errors and speeds up the identification of high-risk items. Visual cues further aid prioritization.

- Seamless Integration of Preventive & Detective Actions: Recommended actions are not just text entries; they become traceable, assignable Polarion Work Items (tasks, requirements, change requests), ensuring follow-through and linkage to design or process changes.

- Living FMEA Documents: Unlike static spreadsheets, FMEAs managed in Polarion via RISKSHEET are dynamic. They can be easily updated as designs evolve or new information becomes available, with full version history.

- Facilitates AIAG & VDA FMEA Compliance: Nextedy RISKSHEET can be configured to fully support the 7-step approach of the AIAG & VDA FMEA Handbook, including structure analysis, function analysis, failure analysis, risk analysis (with AP tables), and optimization.

- Enhanced Collaboration: Cross-functional teams can collaboratively build and review FMEAs within the central Polarion platform, using RISKSHEET as their common workspace.

- Powerful Change Management & Comparison: Leverage Polarion’s versioning, baselining, and Nextedy RISKSHEET’s “compare mode” to track the evolution of your FMEA, understand the impact of design/process changes on failure modes and risks, and demonstrate continuous improvement. This is critical for managing living FMEAs.

Driving Continuous Improvement with FMEA Data

FMEA is not a one-time activity. The data generated, when managed effectively in Polarion with Nextedy RISKSHEET, becomes a valuable asset for:

- Informing Design Decisions: Feeding back high-risk failure modes into the design process.

- Improving Manufacturing Processes: Identifying and mitigating process weaknesses.

- Developing Robust Test Plans: Focusing verification and validation on critical failure modes.

- Lessons Learned: Creating a knowledge base of potential failures and effective controls for future projects.

RISKSHEET ensures this data is accessible, analyzable, and actionable throughout the product lifecycle.

Conclusion: Elevate Your FMEA Practice with Nextedy RISKSHEET in Polarion

Nextedy RISKSHEET transforms FMEA from a potentially cumbersome documentation exercise into a dynamic, integrated, and value-adding engineering discipline within Siemens Polarion ALM. By providing an intuitive interface, automating critical calculations, ensuring robust traceability, and facilitating seamless action tracking, Nextedy RISKSHEET empowers organizations to:

- Conduct comprehensive and consistent FMEAs (DFMEA, PFMEA, etc.) efficiently.

- Meet stringent industry standards like the AIAG & VDA FMEA Handbook.

- Proactively identify and mitigate potential product and process failures.

- Reduce risks, improve quality, and enhance customer satisfaction.

- Maintain a fully auditable and version-controlled FMEA history.

Move beyond static FMEA spreadsheets. Embrace an integrated approach with Nextedy RISKSHEET in Polarion to unlock the full potential of your Failure Modes and Effects Analysis