- Evidence: Industry data on the link between risk and requirements.

- Rationale: The fundamental reasons why risk management shapes your product.

- Benefits: How integrated systems boost efficiency and audit-readiness.

- Justification Toolkit: Key facts to support your case for enhanced risk management tools and processes.

In the demanding world of safety-critical product development – whether it’s automotive systems, medical devices, aerospace technology, or industrial controls – “risk management” is a non-negotiable cornerstone. Often perceived primarily as a compliance activity, its true impact on the engineering lifecycle, particularly on requirements definition, is frequently underestimated.

But what if risk management was less about ticking boxes and more about fundamentally shaping the products you design and build? At Nextedy, we partner with organizations using Polarion ALM to integrate these vital processes, and we’ve consistently observed a profound truth: effective risk management is a primary source of your engineering requirements.

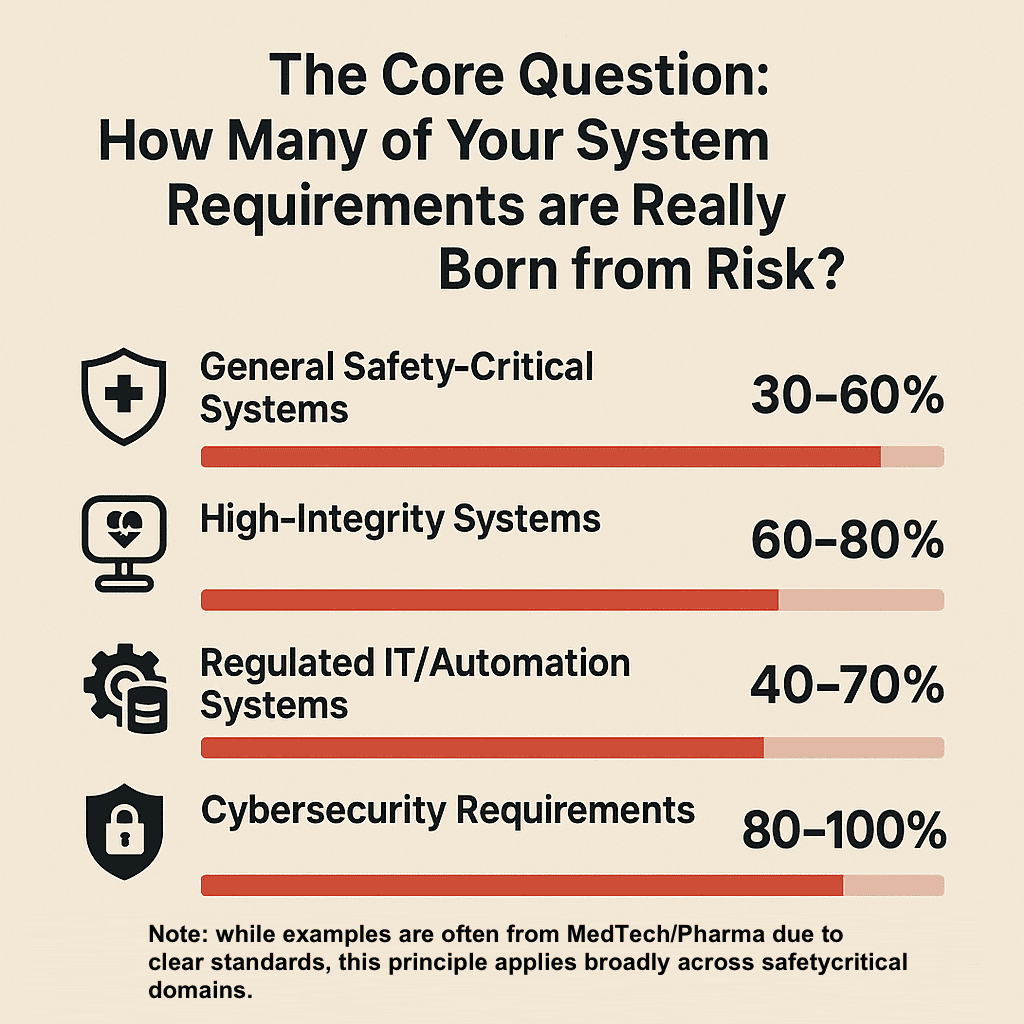

The Core Question: How Many of Your System Requirements are Really Born from Risk?

The answer might be higher than you think. Across various safety-critical domains, a substantial portion of the entire requirements baseline stems directly from the need to mitigate identified hazards, failures, and threats. This isn’t just about a few add-on safety features; it’s about a significant percentage of what defines your system.

While precise figures vary with system complexity and the specific industry standard (like ISO 26262 for automotive, ISO 14971 for medical devices, or IEC 61508 for industrial systems), the trend is clear:

- General Safety-Critical Systems (e.g., Medical, Automotive Functional Safety): Expect 30% to 60% of total system requirements to be direct outcomes of risk control measures identified through processes like HARA (Hazard Analysis and Risk Assessment) or FMEA (Failure Modes and Effects Analysis).

- High-Integrity Systems (e.g., life-support medical devices, automotive ASIL D functions, critical aerospace controls): This percentage often soars to 60% to 80%. Here, requirements ensuring safety and reliability are paramount and dominate the specification.

- Regulated IT/Automation Systems (e.g., Pharma GAMP 5, critical infrastructure): Typically, 40% to 70% of requirements relate to quality, data integrity, availability, and compliance-critical risk controls.

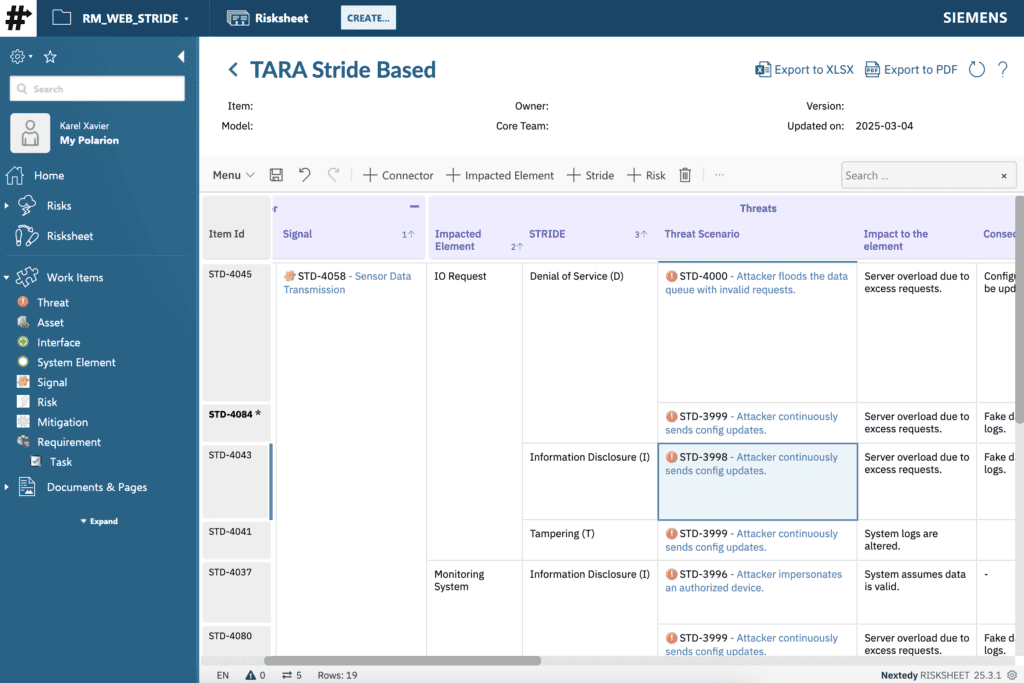

- Cybersecurity Requirements (Across all safety-critical domains): This is where risk is king. An estimated 80% to 100% of all cybersecurity requirements originate from threat modeling (like STRIDE) and Threat Analysis and Risk Assessment (TARA), as they exist to counter specific identified threats.

Why This Is a Fundamental Truth: Key Supporting Principles

This deep connection isn’t accidental; it’s inherent in the design philosophy of safe and secure systems:

- Safety Standards Mandate It: Standards like ISO 26262 (automotive), ISO 14971 (medical), DO-178C (aerospace software), and IEC 61508 (functional safety) all require that identified risks are controlled, and these controls are then specified, implemented, and verified – effectively becoming requirements.

- Failure Mitigation Drives Design: FMEA methodologies, widely used across industries, directly lead to recommended actions that translate into design requirements, process control requirements, or testing requirements.

- Cybersecurity is Inherently Risk-Driven: Unlike features requested by users, security requirements (authentication, encryption, intrusion prevention) are almost exclusively defined in response to potential threats and vulnerabilities identified through risk assessment.

- “Safety by Design” Philosophy: The most effective way to build safe systems is to design safety in from the start, not add it as an afterthought. This means risk analysis directly informs architectural choices and functional requirements.

The Critical Insight for Your Team (and Your Management):

Recognizing that a large fraction of your engineering effort is dedicated to fulfilling risk-derived requirements has profound implications:

Justifying Investment in Integrated ALM & Risk Tools: If such a significant portion of your product definition comes from risk, your risk management and requirements engineering tools and processes must be seamlessly integrated. Disconnected systems are a recipe for inefficiency, traceability gaps, and increased compliance burdens.

Fact for your Manager: “Investing in tools that integrate risk management (like HARA, FMEA, TARA) with requirements engineering (like Polarion ALM enhanced by Nextedy solutions) is not an add-on cost. It’s an investment in efficiently managing 30-80% of our core product specification and ensuring robust compliance.”

Elevating Risk Management’s Strategic Role: It’s not just a specialist function; it’s a key input that shapes product architecture and defines a large set of critical requirements. This fosters vital collaboration between safety, security, systems, hardware, and software engineers.

Fact for your Manager: “Our risk assessment activities directly generate a substantial part of our engineering backlog. Streamlining this with integrated tools means faster, more robust, and more compliant development outcomes across all safety-critical projects.”

Optimizing Resource Allocation: Understanding the true origin of requirements helps allocate appropriate time, budget, and expertise to proactive risk management throughout the entire product lifecycle.

Fact for your Manager: “By acknowledging the deep link between risk and requirements, we can strategically invest in front-loading risk mitigation activities, ultimately reducing costly late-stage changes and project overruns.”

Strengthening Your Safety and Security Culture: When the entire organization clearly sees how risk analysis translates into tangible product requirements and design choices, it reinforces a culture where safety and security are integral, not optional.

Breaking Down Silos: The Path to Integrated Excellence in Safety-Critical Development

The evidence is compelling: risk management is a primary engine that drives the detailed specification of your safety-critical products.

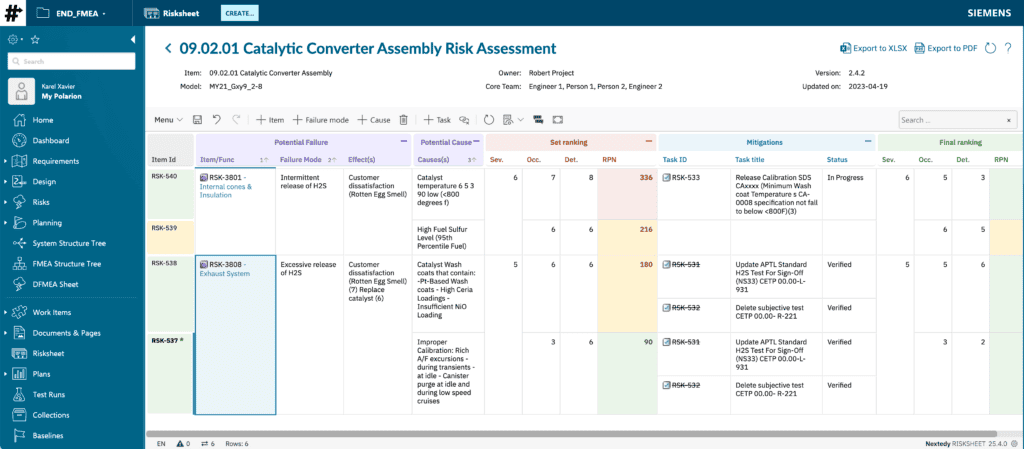

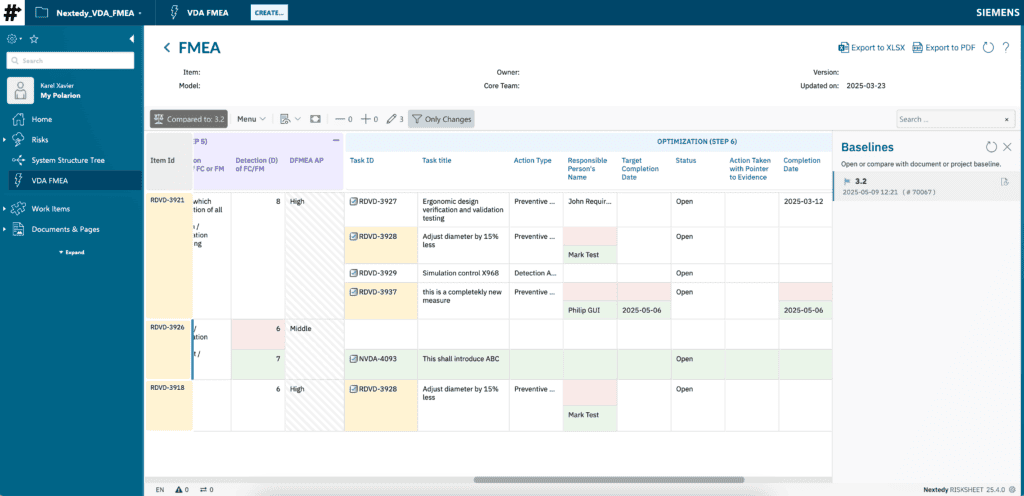

By leveraging a unified platform like Polarion ALM, significantly enhanced by specialized tools such as Nextedy RISKSHEET (which provides an intuitive and powerful interface for diverse risk methodologies like HARA, FMEA, TARA, and CVSS), your organization can:

- Achieve seamless, bi-directional traceability from hazards, failure modes, or threats to their mitigating controls and verified requirements.

- Enhance collaboration and communication across all engineering disciplines and safety/security teams.

- Streamline compliance and audit preparations with a readily accessible, single source of truth.

- Build inherently safer, more secure, and higher-quality products, more efficiently.

It’s time to fully leverage the power of your risk management activities as a core driver of engineering excellence.