- The Standard’s Demands: How ISO 26262, ASPICE, and machinery safety standards (e.g., ISO 13849-1) mandate structured project management.

- Common Operational Pitfalls: Identifying dangers of disconnected project oversight in safety-critical automotive and machinery development.

- The Path to Control: Understanding why an integrated ALM and Project Management approach (e.g., Polarion ALM with Nextedy enhancements) is crucial.

- Internal Justification Points: Key facts to support investment in unified project and safety lifecycle management within your organization.

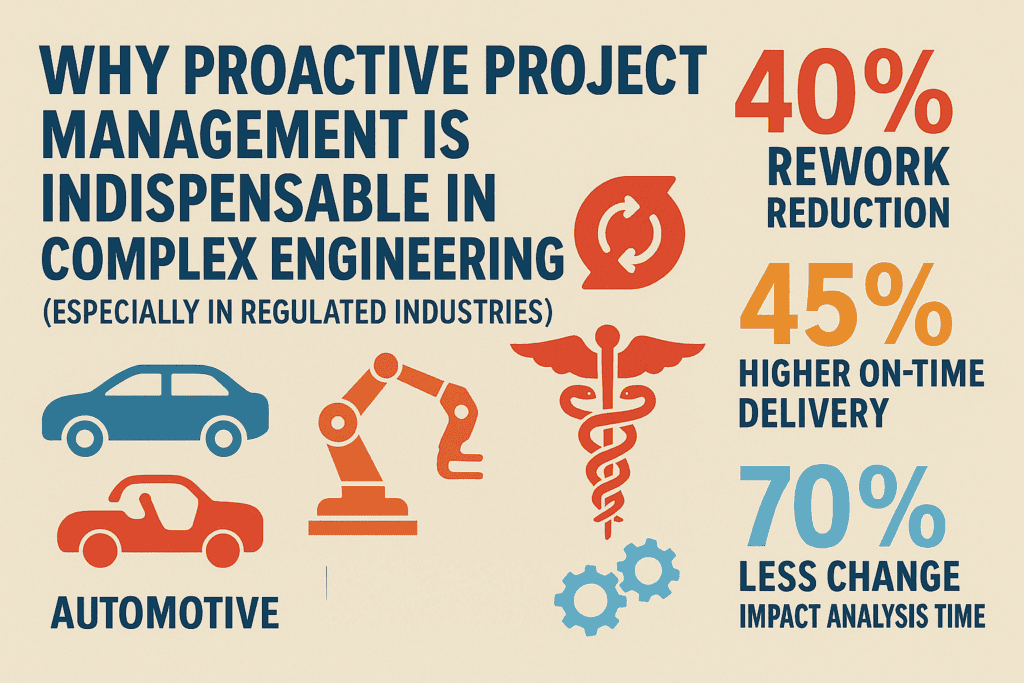

Why Proactive Project Management is Indispensable in Complex, Regulated Engineering

Delivering today’s advanced automotive, machinery and medical-device systems on time, on budget and fully compliant demands more than great engineers—it requires disciplined planning, transparent execution tracking and rapid response to change. In safety-critical industries governed by standards like ASPICE MAN.3, ISO 26262 Part 2 and IEC 61508/ISO 13849-1, project management isn’t optional—it’s explicitly mandated.

How the Standards Enforce Project Management

- Automotive SPICE (MAN.3): Scope‐definition, resource planning, progress monitoring and corrective action—Level 2 means “Managed.”

- ISO 26262 (Part 2): A dedicated Safety Plan with schedules, roles (Safety Manager), competency requirements and audit records.

- IEC 61508 / ISO 13849-1: A Functional Safety Management Plan defining phases, responsibilities, change control and validation for required SIL/PL.

Table: How Key Standards Reinforce Core Project Management Principles for Safety

| Standard / Model | Primary Domain(s) | Key Project Management Principles Emphasized for Safety | Typical Outcome / Deliverable Highlighting PM |

| ISO 26262(Functional Safety) | Automotive (E/E Systems) | • Detailed planning of all safety lifecycle activities. • Clear assignment of roles & responsibilities (incl. Safety Manager). • Management of safety requirements, verification, and change control. • Competency management. | Safety Plan, Confirmation Measures Records |

| Automotive SPICE (ASPICE) | Automotive (Software/Systems) | MAN.3 (Project Management): Scope definition, feasibility, activity/resource planning, progress monitoring, corrective actions. • Configuration Management (SUP.8), Change Request Management (SUP.10). | Project Plan, Progress Reports, ASPICE Capability Level 2 (“Managed”) |

| IEC 61508(Functional Safety) | Industrial (Generic E/E/PE Systems) | • Planning of the full safety lifecycle. • Requirements for Functional Safety Management (FSM). • Verification, validation, and configuration management planning. • Competency assessment. | Functional Safety Management Plan (Safety Plan) |

| ISO 13849-1 / IEC 62061(Machinery Safety) | Machinery Control Systems | • Structured safety lifecycle with defined phases. • Definition of responsibilities for safety tasks. • Planning for risk assessment, design, implementation, and validation of safety functions. | Functional Safety Plan (for safety-related parts of control systems) |

Common Operational Challenges Stemming from Inadequate Project Management Integration

Without tightly integrated project management, even technically proficient teams in automotive and machinery development can face significant operational hurdles that jeopardize safety, compliance, and project timelines:

Challenge 1: Underestimation and Ad-Hoc Execution of Safety Activities

Observation: Safety tasks (e.g., HARA, FMEA, safety concept development, verification reviews) are not detailed in initial project plans or are treated as flexible items.

Consequence: Missed or delayed critical safety analyses, leading to late discovery of design flaws, significant rework, schedule overruns, and potential gaps in the safety case during assessments. As one LSI development firm noted, costs can double if ISO 26262’s “Safety Concept” phase is not adequately planned upfront.

“Upfront ISO 26262 Planning ↓ Late-Stage Rework by ~40%

Research shows that immature requirements processes can add 40–50 % extra rework cost to a project. Embedding every ISO 26262 activity into the plan from day 1 curbs that late-stage rework by roughly 40 % “

Challenge 2: Ambiguous Responsibilities for Safety Deliverables

Observation: Lack of clearly assigned owners for specific safety analyses, reviews, or documentation.

Consequence: Critical activities are overlooked, performed informally, or lack proper sign-off, leading to unvalidated requirements or incomplete safety arguments.

“Clear Accountability → 3× Higher On-Time Delivery

PMI’s Pulse of the Profession finds that “champion” organizations—where roles are unambiguous—achieve project success (on-time, on-budget, full scope) 92 % of the time versus 33 % for underperformers “

Challenge 3: Poor Management of Interfaces and Supplier Contributions

Observation: Dependencies between internal teams (system, HW, SW) or with external suppliers regarding safety deliverables are not actively tracked or aligned.

Consequence: Integration failures, discovery that supplier-provided safety evidence is missing or inadequate, or misaligned assumptions leading to safety gaps (e.g., an OEM assuming a supplier handles a safety mechanism the supplier wasn’t contracted for).

“Embedded SQEs & Tracked Deliverables ↓ Supplier Escapes 68% & Scrap/Rework Costs 69%

In one aerospace case, stationing Supplier Quality Engineers on-site and integrating supplier deliverables into a central plan cut supplier escape rates by 68 % and scrap/rework costs by 69 % over 24 months”

Challenge 4: Reliance on Disconnected Document Storage (e.g., Shared Drives)

Observation: Safety-critical specifications, analyses, and test evidence are stored in shared folders without robust version control or auditable change history.

Consequence: Loss of traceability, “version chaos” (teams working from different document versions), inability to demonstrate controlled development during audits, and risk of inadvertent data corruption or loss. This directly contravenes configuration management expectations of ASPICE (SUP.8) and ISO 26262.

“Central ALM ↓ Traceability Effort by 80%

Spansion’s migration to Polarion ALM delivered an 80 % reduction in time spent on traceability management—automating version control and audit trails in one unified platform.“

Challenge 5: Ineffective Change Management Processes

Observation: Requirements or design changes are implemented without a formal safety impact analysis or without ensuring all linked safety analyses and verification activities are updated.

Consequence: Introduction of new, unanalyzed hazards; invalidation of existing safety arguments; failure to meet regression testing needs. This is a common source of non-compliance.

“Automated Safety Analysis ↓ Analysis Time by 50%

Using tools to analyze and automate impact and safety-analysis cuts the time required for functional-safety verification by up to 50 % “

The Imperative of Integration: Connecting Project Management with Engineering Reality

Functional safety standards and process models like ASPICE don’t just imply integration; they effectively mandate it. Project management must be interwoven with requirements engineering, system design, and verification & validation:

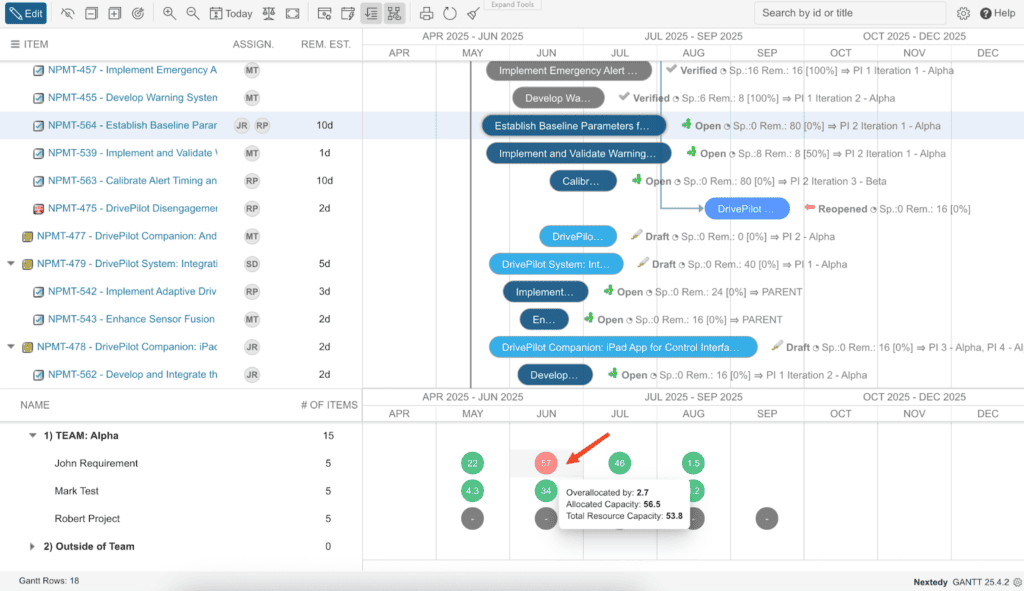

Ensuring End-to-End Traceability:

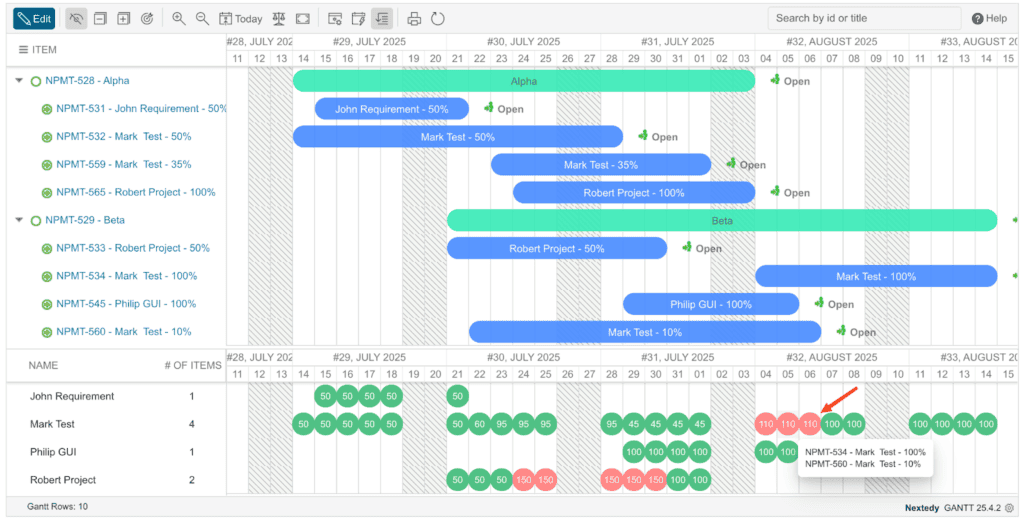

The project plan isn’t just a list of dates; it must reflect the actual work. Using Polarion ALM augmented by Nextedy’s GANTT and PLANNINGBOARD solutions allows project schedules to be directly linked to requirements, safety goals, risks, test cases, and their statuses.

“One leading semiconductor OEM cut its traceability effort from 20–25 % of project time down to just 5–10 % by adopting an ALM platform with built-in end-to-end traceability—generating full requirement-to-test coverage reports at the click of a button”

Facilitating V-Model Alignment:

Project plans developed with integrated tools can explicitly map development phases to their corresponding verification and validation activities, enabling effective management of quality gates and ensuring V&V is not an afterthought.

“Survey shows V-Model adoption leads to about a 30 % drop in project-related issues and up to 30 % lower overall project costs by catching defects early”

Creating a Closed-Loop Change Management System:

When a safety requirement changes in Polarion, an integrated project management system can automatically highlight affected tasks, trigger impact analyses, and ensure the project plan is updated to include necessary rework and re-verification.

“A 2024 Gartner report found 70 % of organizations using automated solutions cut their change-impact analysis time by 50 %, freeing teams to focus on strategic work “

Providing Robust Evidence for Compliance:

The ultimate output of an integrated system is the readily available, trustworthy evidence needed for safety assessments, audits, and certifications. Dashboards and reports can pull live data showing requirement coverage, test progress, risk mitigation status, and adherence to the safety plan.

“Sonova’s Polarion deployment slashed compliance-doc preparation time by 80 %, dramatically accelerating audit readiness “

Conclusion: Integrated Project Management as a Strategic Enabler for Functional Safety

In the demanding automotive and machinery sectors, robust project management is not merely administrative overhead; it is a strategic enabler of functional safety. The rigorous demands of standards like ISO 26262, ISO 13849-1, and ASPICE necessitate a planned, monitored, and integrated approach to ensure that safety goals are met systematically.

The pitfalls of disconnected management—ranging from misestimated tasks and traceability gaps to uncontrolled changes—can lead to severe consequences, including project failures, non-compliance, and compromised safety. Conversely, adopting an integrated solution, such as Siemens Polarion ALM enhanced with Nextedy’s specialized project and risk management capabilities (Nextedy GANTT, PLANNINGBOARD, and RISKSHEET), empowers organizations. It allows for:

- Unified planning and tracking of all safety and development activities.

- Real-time visibility into progress, dependencies, and potential roadblocks.

- Demonstrable traceability across the entire safety lifecycle.

- Efficient management of change and its impact on safety.

For leaders and managers in automotive and machinery, championing investment in such integrated processes and tools is key to fostering a proactive safety culture, navigating complex global regulations, and ultimately delivering innovative products that are both high-quality and demonstrably safe by design.