In the race to deliver the future of mobility, we’ve rightly embraced AUTOSAR as the backbone for our most complex automotive software. But in our pursuit of its benefits—modularity, reusability, scalability—we’ve allowed a critical safety process to become a dangerous “ghost document”: the FMEA.

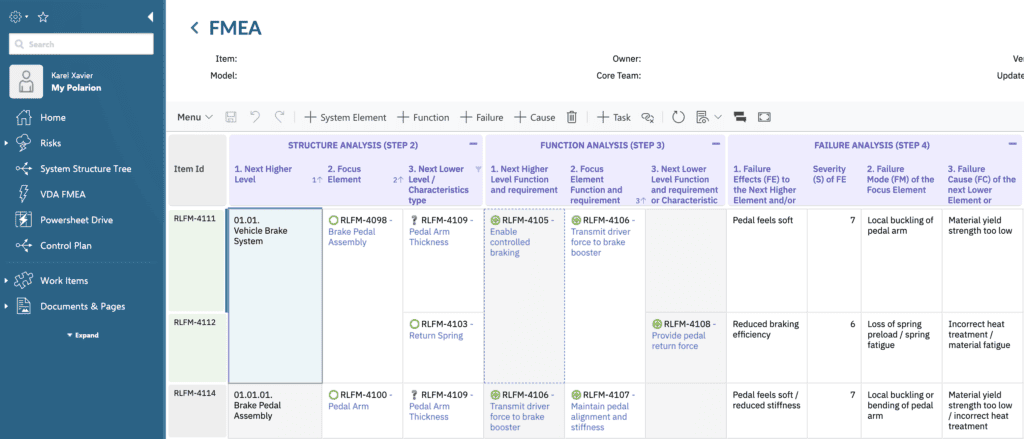

Too often, the FMEA is a spreadsheet living in isolation or a generic module in a tool that doesn’t understand the intricate reality of embedded software. It exists to be “compliant,” but it doesn’t truly connect to the engineering reality. This isn’t just an inefficiency; it’s a profound risk. A disconnected FMEA creates an illusion of safety while leaving your designs exposed.

It’s time for a reality check.

5 Questions to Pressure-Test Your AUTOSAR FMEA

Ask your teams these questions. If the answers are not immediate, confident, and backed by data, your FMEA is not the asset you think it is.

1. “If a high-severity failure mode is identified in our FMEA, can you show me—in under 30 seconds—the exact Technical Safety Requirement and the specific SWC it impacts?”

If the answer involves searching through spreadsheets and manually cross-referencing documents, your FMEA is not integrated. It’s an island, creating a critical delay between identifying a risk and acting on it.

2. “When a requirement changes, how does our FMEA automatically flag the potential impact on our risk assessment?”

If this process is manual, it’s already broken. In the dynamic world of automotive development, this gap means your risk analysis is perpetually out of sync with your design reality, leaving you vulnerable to unforeseen consequences.

3. “Can our FMEA distinguish between a generic hardware failure and a specific AUTOSAR failure, like an SWC port providing incorrect output or a BSW service malfunction?”

If your FMEA uses generic failure modes, it’s blind to the most critical software-specific risks. You cannot mitigate what you cannot accurately describe, and your AUTOSAR architecture has unique failure points that demand a specialized vocabulary.

4. “How do you prove to an auditor that the rigor defined by an ASIL D rating has been applied to every dependent element, from the requirement down to the Runnable?”

If the answer requires a frantic, manual compilation of evidence, your process is not only inefficient but fragile. A robust safety case relies on live, unbroken traceability—not on heroic efforts before an assessment.

5. “Do our engineers see the FMEA as a valuable design tool, or as a bureaucratic task to be completed after the real work is done?”

This is the most crucial question. If your FMEA isn’t actively used by engineers to make better design decisions, it has failed. The goal is not a perfect document; it is a safer, more resilient system. This only happens when risk analysis is a practical, integrated part of the daily engineering workflow.

From a Liability to a Competitive Advantage

If answering these questions was uncomfortable, you’re not alone. We have been conditioned to treat FMEA as a compliance checkbox.

But what if we treated it as the bedrock of our safety case?

By embedding FMEA directly into the ALM environment where your teams already work, it transforms. It ceases to be a static document and becomes a dynamic, living asset that:

- Drives Precise, Actionable Insights: Directly link AUTOSAR-specific failure modes to the requirements that prevent them, eliminating ambiguity and rework.

- Guarantees End-to-End ASIL Consistency: Ensure the rigorous demands of ISO 26262 are automatically propagated and traced, making compliance a natural outcome of good engineering, not a separate activity.

- Provides Real-Time Impact Analysis: Instantly see the ripple effect of any change, allowing your teams to adapt with speed and confidence.

- Builds an Effortless, Auditable Safety Case: Present a single source of truth that demonstrates a clear, undeniable trail from hazard identification to verified implementation.

Your AUTOSAR projects are too complex and your safety goals too important to be gambling on a disconnected process. It is time we demand that our risk management tools speak the language of our software and empower our engineers, rather than burdening them.

The future of automotive safety isn’t about better spreadsheets; it’s about integrated, intelligent, and actionable risk management.